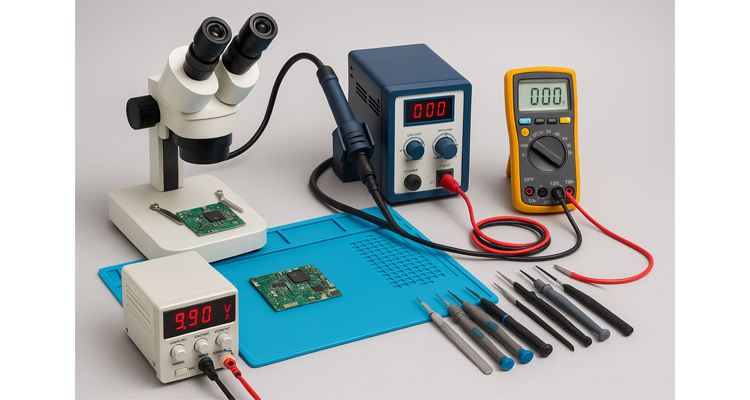

Essential Tools for Motherboard Repair: What You Need & Why

Setting up a reliable repair bench begins with choosing the right tools. Below is a practical guide to the core categories you’ll use daily – with quick tips, key specs to watch, and direct links to browse each category on GSMBAZAR.

Quick Spec Checklist (at a glance)

| Tool | Key Specs / Features | Why It Matters | Browse |

|---|---|---|---|

| Microscope | Stereo 7–45x / 10–120x, trinocular (camera), LED ring/boom stand | Critical for microsoldering, pad/trace inspection, and fine alignment | Microscopes |

| Hot Air Gun / SMD Rework | 100‑450°C, 120‑300L/min airflow, closed-loop control, memory presets | Safe IC removal/reflow without overheating surrounding parts | SMD Stations |

| DC Power Supply | 0–30V / 5–6A, CV/CC modes, low ripple, fast OCP/OVP | Board testing, battery simulation, current-draw diagnostics | DC Power Supply |

| Repair Mat / Insulation Pad | ESD-safe, heat resistant, magnetic zones, parts trays | Protects boards, organizes screws/ICs, resists heat during rework | Repair Mats |

| Soldering Station | 200–500°C, rapid heat, sleep/auto-off, T245/900M tip ecosystem | Clean joints, fast recovery, safer to components | Soldering Stations |

| Multimeter | True RMS, diode/continuity, auto-range, capacitance, backlit | Find shorts, check rails, validate repairs quickly | Multimeters |

| Screwdrivers | Precision bits (PH, P, Torx), magnetic tips, anti-slip grip | Safe device opening and reassembly without stripping screws | Screwdrivers |

| Tweezers | ESD-safe, fine tips (straight/bent), anti-magnetic stainless | Precise placement and removal of tiny SMD components | Tweezers |

| Blades / Pliers / Brushes | Ultra-thin blades, flush cutters, anti-static brushes | Safe scraping/cleaning, cutting jumpers, tidy work area | Blades & Pliers |

Tool-by-Tool Breakdown

Microscope

A stereo microscope (preferably trinocular if you plan to record or stream) is the foundation of microsoldering. Look for 7–45x or 10–120x magnification, a ring light or boom-arm illumination, and plenty of working distance around the board.

- Common options: 10–120x trinocular with ring light; 7–45x stereo on boom stand.

- Tips: Add an HDMI camera for documentation and training.

Hot Air Gun / SMD Rework Station

For reflowing and removing SMD components. Seek closed-loop temperature control, a wide 100‑450°C range, adjustable airflow, and nozzle variety for different IC sizes.

- Common options: 2-in-1 solder+hot air combos; standalone 700W hot air stations.

- Tips: Use preheating and shielding to protect nearby components.

DC Power Supply (Bench Power)

Choose 0–30V with 5–6A headroom, CV/CC modes, and clear V/A/W readouts. You’ll simulate batteries, power boards, and watch current draw to diagnose shorts or boot issues.

- Common options: 30V/5A lab supplies; 30V/6A advanced with protections.

- Tips: Keep leads short, use banana-to-croc clips, and set current limits.

Repair Mat / Insulation Pad

ESD-safe mats protect sensitive chips, while heat-resistant silicone pads tolerate hot air work. Built-in trays and magnetic zones keep screws and ICs sorted.

- Common options: Large silicone mats with parts trays; compact ESD table mats.

- Tips: Use labeled compartments for repeat jobs to speed up reassembly.

Soldering Station

A reliable station ensures fast thermal recovery and precise control (typically 200–500°C). Look for sleep/auto-off, easy tip changes, and a tip family (e.g., T245, 900M) that matches your work.

- Common options: 75–120W digital stations; 2-in-1 solder+hot air combos.

- Tips: Keep tips tinned; use quality flux and leaded solder where allowed.

Multimeter

A True RMS, auto-ranging meter with diode, continuity, capacitance, and a backlit screen will cover 90% of bench checks. Pair with sharp probes for tiny test pads.

- Common options: Compact auto-range meters; bench meters with PC logging.

- Tips: Use needle probes and hook clips for secure contact.

Precision Screwdrivers

A set with phone-specific bits (Phillips, Pentalobe, Torx/Torx Security) and magnetic tips prevents damage and speeds teardown/assembly. Anti-slip handles improve control.

- Common options: Single high-precision drivers; multi-bit kits in a compact case.

- Tips: Keep a screw chart or tray to avoid mixing lengths.

Tweezers

Choose ESD-safe, anti-magnetic stainless steel tweezers with fine straight and curved tips. They are essential for placing 0201 passives and handling flex cables or shields.

- Common options: ESD-11 straight, ESD-15 bent, ultra-fine 2A/5 sets.

- Tips: Replace worn tips; keep a dedicated flux-clean pair.

Knife Blades, Brushes & Pliers

Ultra-thin blades help remove adhesives and shields; flush cutters/pliers manage jumpers and wires; ESD brushes clean flux residue without static risk.

- Common options: 009/006 degumming blades; precision flush cutters; soft ESD brushes.

- Tips: Always cut away from traces; use IPA and lint-free swabs for cleanup.

Final Tips

- Invest in ESD protection (mat, strap) to prevent latent damage.

- Calibrate/maintain tools regularly; replace worn tips, nozzles, and probes.

- Label and organize parts to reduce turnaround times and errors.